Threading

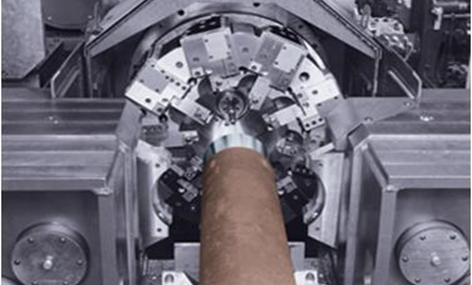

We offer state of the art process controlled manufacturing on a full range of API and Premium connections. We provide comprehensive threading services for all sizes and weights of drill pipes, casing and tubing. Our threading cell is capable of

- Optimised for large quantities

- Full length API & customized length Premium threading

- Swage and Stress relieving processes for integral connections

- End finishing and Torquing operation

- The CNCs can accommodate pipe fed through the machine from 3.5″ to 10-3/4″ outer diameters (O.D.)

Machining

We offer precision machining for various diameter sizes of materials. We are a licensed repair shop by major thread technology companies and a preferred supplier to many oilfield operators and service companies. Our equipment ranges from manual machines to state of the art CNC lathes to meet small and large production requirements.

- General machining on a wide range of materials

- OEM tool and equipment manufacture

- Repair and overhaul

Fabrication

Our fabrication capabilities range from precision machining, fabrication, welding to final assembly.

- Crossovers: short length of casing or tubing as connectors to various sizes, weight or types at a certain point in a string general machining from a wide range of materials.

- Threaded Profile Nipples: run into the well on completion tubing to provide specific landing location for subsurface flow control equipment. OEM tool and equipment manufacture.

- Pup Joints: use to adjust the length of the drill string to elevate the rotary table for easy surface handling and drilling tasks

- Drill Collars: use as a component of the bottom hole assembly (BHA) to provide weight on bit (WOB), BHA directional control, hole size integrity, drill string clearance, drill string compressive and torsional load.

Special Process Services

We are capable to provide a wide range of special services and our scope include:

- Copper electroplating*

- Manganese phosphating

- Zinc phosphating

- Ceramic bead blasting

- Low stress dot stamping

- Paint stencilling

- Drifting

- Swaging

- Stress relieving

- Turning & Boring

- Honing

- Milling

- Vibro-etching

*Subcontracted services as part of end product

OCTG & Drill Pipes Storage Management

We offer drill pipes storage and management services on our 1.3 acres open yard facility. This value added service further enhance our one stop shop concept to meet our customers growing demand. Our seamless process will include end-to-end third-party logistics coordination for customers.

Tubular Accessories

We manufacture and supply a wide range of tubular accessories to the oil and gas industry including, but not limited to, the following:

- Variety of Crossover Subs

- Casing / Tubing / Drill Pipe Pup Joints

- Blast Joints / Flow Couplings

- Lift Plugs / Lift Caps

- Cementing Swages

- Stabbing Guides

- Casing / Tubing Drifts

Sales and Supplies

We are connected to a wide range of sourcing networks and we are capable to supply most types of OCTG, drilling stems (drill collars, drill pipes), offshore basket, float equipment and others.